Plastic Before 1862? The Shocking Truth

Greetings! Did you know that plastic existed before 1862? The astonishing facts will change your perspective.

Source www.bbc.co.uk

The Invention of the First Man-Made Plastic in 1862

Plastic is one of the most versatile materials that is widely used in various industries. But, have you ever wondered who invented the first man-made plastic? What were the circumstances and reasons behind its development? In this article, we will delve deeper into the discovery of the first man-made plastic in 1862 and its impact on society.Discovery of Plastic

In the mid-19th century, the demand for natural resources like ivory, tortoise shell, and bone created a pressing necessity for a material that could replace these natural resources. Alexander Parkes, an English inventor, was trying to find an alternative to replace ivory in billiard balls. He accidentally discovered the first form of plastic, named Parkesine in 1856. Parkesine was made by dissolving cellulose nitrate in solvents like alcohol and camphor. The resultant substance could be molded into any shape once it hardened. It had properties similar to natural materials like ivory and horn and was used as a substitute for these luxury materials. In 1862, he exhibited his invention at the International Exhibition in London, where it garnered immense attention.Parkesine was considered a breakthrough material and was used in the production of a wide range of products, including combs, buttons, and even umbrellas. Despite its versatility, Parkesine had significant drawbacks. It was expensive to produce, brittle, and highly flammable. It needed to be stored in a safe and cool environment.Development of Commercial Plastic Manufacturing

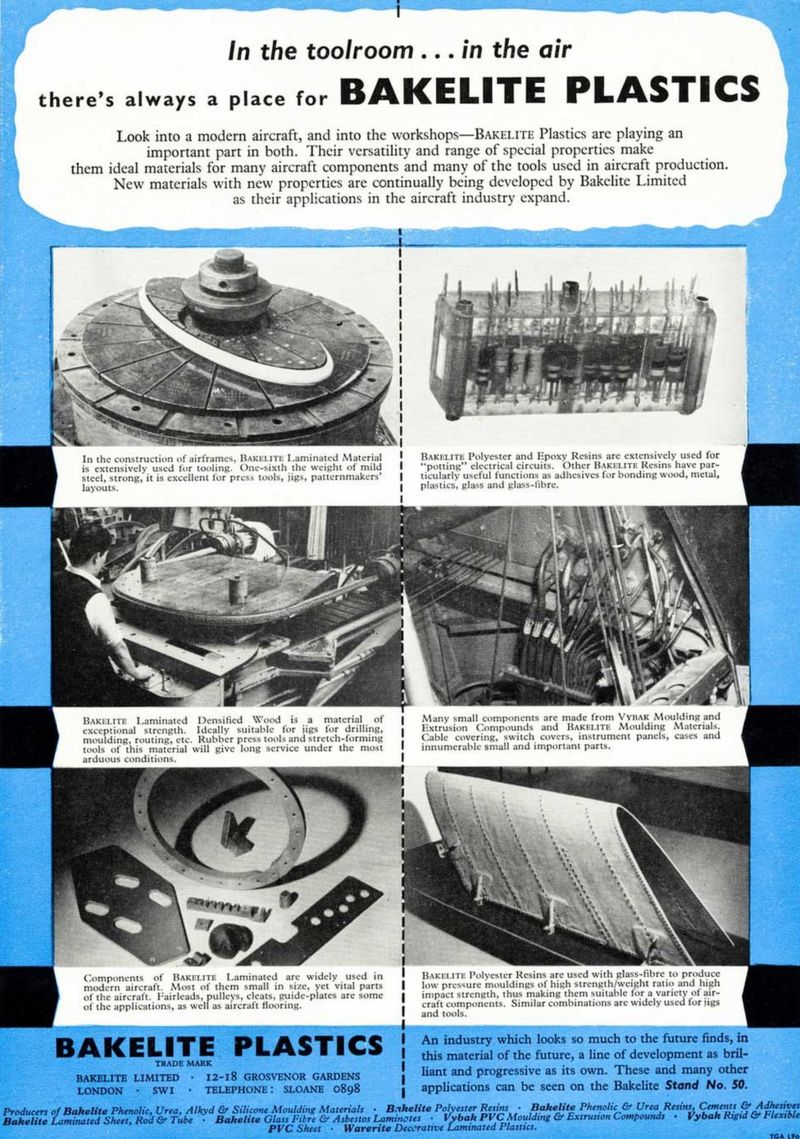

In 1907, Leo Baekeland revolutionized the field of plastic manufacturing by inventing Bakelite. Bakelite was the first synthetic plastic that was made from coal tar and formaldehyde. It was the first plastic that could be mass-produced and was made in various colors and shapes. Bakelite became popular in the electrical industry, where it replaced materials like ivory and porcelain in electrical insulators.The popularity of Bakelite encouraged the development of other synthetic polymers like PVC (polyvinyl chloride), polystyrene, and nylon. These new materials were comparatively easy to produce, durable, and could be molded into any shape. Plastic manufacturing became a multimillion-dollar industry, and it replaced natural materials like wood, metal, and glass in various industrial and consumer products.Revolutionizing Industries

The development of plastic revolutionized various industries like healthcare, aerospace, transportation, and fashion. The medical industry has benefited from plastic in the production of various medical devices like syringes, implants, and surgical instruments. It has also contributed to the development and mass-production of affordable medicines.The aerospace and automotive industries have utilized plastic parts to reduce the weight of vehicles, which has led to better fuel efficiency. The use of plastic in the fashion industry has led to the production of synthetic fabrics like polyester, nylon, and spandex. These materials are affordable, durable, and easy to maintain. However, plastic waste from the packaging industry has caused an environmental crisis. Millions of tons of plastic waste end up in landfills, oceans, and other natural habitats, where it takes hundreds of years to decompose. Single-use plastics like straws and bags have contributed to the pollution of water bodies, and it has endangered marine life.In conclusion, the discovery of the first man-made plastic by Alexander Parkes in 1862 set a precedent for the development of synthetic materials that have revolutionized various industries. However, the misuse and improper disposal of plastic waste have led to an environmental crisis that needs urgent attention. Proper recycling and responsible use of plastic can help to mitigate the environmental impact of this material.The Impact of the First Man-Made Plastic

Modern Materials Science

When it comes to modern materials science, plastic has become one of the most prevalent and versatile materials in today’s world. It has revolutionized the manufacturing process, paving the way for new innovative products to be made in a faster, more cost-effective manner. Plastic has become a crucial component in a variety of industries, including automotive, electronics, food packaging, and medical equipment.One of the major benefits of plastics in modern materials science is that they can be easily molded into various shapes and sizes. This versatility has enabled engineers and designers to be more creative with their designs and has allowed manufacturers to create products that would have been impossible to make with traditional materials such as metal or wood.Role in Modern Industry

Plastics have revolutionized a wide range of industries, changing the way products are manufactured and consumed. The medical industry, for example, relies heavily on plastic for a variety of equipment such as syringes, IV tubes, and surgical instruments. The automotive industry uses plastics for components such as dashboards, bumpers, and seatbelts, which have helped improve fuel efficiency and reduce emissions.Plastics have also played a key role in the consumer goods industry, where they are used for packaging, toys, and household appliances. Their cost-effectiveness, versatility, and durability have revolutionized the way these products are manufactured and consumed.Environmental Impacts of Plastics

Despite the numerous benefits plastic has brought to modern industry, the environmental impacts of plastic waste are becoming increasingly concerning. The world produces millions of tons of plastic waste each year, with much of it ending up in landfills, oceans, and other ecosystems. This is having a significant impact on wildlife and natural habitats, with animals and plants being harmed by plastic pollution.One of the biggest environmental concerns related to plastics is the longevity of their lifespan. Many plastic products can take hundreds of years to decompose, leading to the accumulation of plastic waste in the environment. This accumulation can cause a variety of environmental problems, including air and water pollution, habitat destruction, and endangerment of wildlife species.To combat this issue, companies and governments are exploring alternatives to plastic, such as biodegradable plastics and reusable materials. They are also implementing measures such as recycling and waste reduction programs to help reduce the amount of plastic waste entering the environment.In conclusion, while the first man-made plastic may have revolutionized the modern world, it is important to acknowledge and address the environmental issues associated with plastic waste. By exploring sustainable alternatives and reducing our reliance on plastic, we can work towards a healthier and more sustainable future for ourselves and the planet.Did the inventor of plastic also invent the modern key?The Advancements in Plastic Manufacturing Technology

Additives and Compounds

Plastic manufacturing has come a long way since the first man-made plastic was invented in 1862. Today, plastic can be mixed with various additives and compounds to provide specific properties and characteristics, making them suitable for a wide range of applications. These additives and compounds include fillers, plasticizers, stabilizers, and flame retardants, just to name a few.

Fillers are materials that are added to plastic to improve its strength and durability. Common fillers include glass fibers, carbon fibers, and mineral powders. Plasticizers, on the other hand, are added to plastic to make them more flexible and easier to shape. Stabilizers are used to prevent plastic from degrading due to exposure to light, heat, or oxygen. Flame retardants are added to plastic to make them less flammable and safer to use in fire-prone environments.

Blow Molding and Injection Molding

Blow molding and injection molding are two of the most common plastic manufacturing techniques used to create a wide variety of plastic products.

Blow molding is a process in which melted plastic is injected into a hollow mold that is then inflated using compressed air. This technique is commonly used to create plastic bottles and containers. Injection molding, on the other hand, involves injecting melted plastic into a mold under high pressure. The plastic is then cooled and solidified, creating a finished product. Injection molding is used to create everything from vehicle parts to medical devices.

3D Printing with Plastics

The emergence of 3D printing technologies has revolutionized the way products can be made, including the use of various types of plastic materials for additive manufacturing. 3D printing technology allows manufacturers to create complex shapes and parts that would be difficult or impossible to produce using traditional manufacturing techniques.

There are several types of plastics that can be used in 3D printing, including polylactic acid (PLA), acrylonitrile butadiene styrene (ABS), and nylon. PLA is a biodegradable plastic that is commonly used in 3D printing because it is easy to print with and produces high-quality prints. ABS is a stronger plastic that is commonly used in 3D printing for creating durable parts. Nylon is a flexible, strong, and lightweight material that is commonly used in 3D printing for creating parts that require flexibility, such as phone cases and hinges.

In conclusion, advancements in plastic manufacturing technology have made plastic products more diverse, durable, and affordable than ever before. From the use of various additives and compounds to the implementation of blow molding, injection molding, and 3D printing techniques, plastic has cemented its place as a vital material in modern manufacturing.

Were plastics used in the earliest forms of video recording?

Post a Comment for "Plastic Before 1862? The Shocking Truth"